Share to:

Related Products

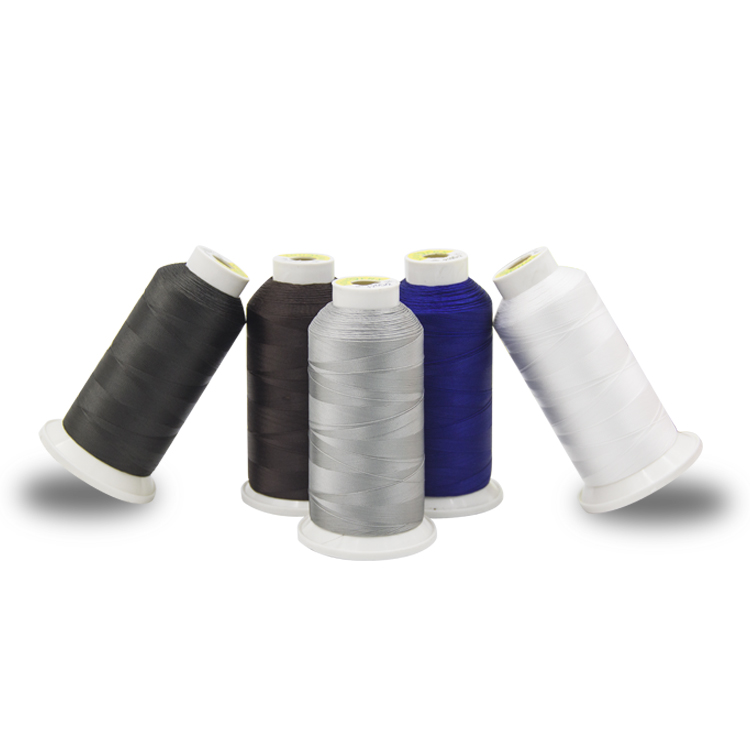

Cheap product multi-color 100% draw textile polyester yarn

LQ-0401

Price: From $0.66

Delivery time: 9-20 days after payment

MOQ: 500 KG

Use:Embroidery, knitting, sewing, weaving

Twist:S/Z

Evenness:Excellent evenness

Yarn count:150d/144f

Strength:3.00-4cn/dtex

Place of Origin:Guangzhou

Color:Dope dyed colors & dope dyed black

Certification:ISO9001:2008 & OEKO TEX STANDARD 100

Method of calculation of textile yarn

1. Units

(1), fixed length system:

A. Tex: The number of quality grams for a yarn of 1000 meters in length at a predetermined return rate is called a special number.

Common: Ntex =(G/L) × 1000

In the formula: G is the weight of the yarn(g), L is the length of the yarn(M)

B. Dannier: The number of grams of mass of 9,000 meters of yarn at a predetermined return rate is called the number of digits.

Common: Nden =(G/L) × 9000

In the formula: G is the weight of the yarn(g), L is the length of the yarn(M)

(2) Definitive system:

A. Public branch number(public branch): 1 gram of yarn(silk) has a length of meters.

Common: Nm = L/G

In the formula: 1 is the length(M) of the yarn (silk), and G is the weight(g) of the textile (silk)

B. English number(English number): The number of 840 yards of length that a pound of yarn has.

Common: Ne =(L/G) × 840

In the formula: L is the length(code) of the yarn(silk) and G is the weight(pound) of the yarn(silk).

2, Unit conversion

A. Special number Ntex and British branch Ne

Ne = C/Ntex(C is a constant, chemical fiber is 590.5, cotton fiber is 583, if it is mixed yarn can be calculated based on mixing ratio, Such as: T/JC(65/35) 45S yarn C = 590.5 * 65 % + 583 * 35 % = 588, and then calculated by formula)

B. British branches Ne and metric branches Nm

Pure chemical fiber: Ne = 0.5905 N M Pure cotton: Ne = 0.583N M

Mixed yarn: such as T/JC(65/35) 45S Ne =(0.5905 * 65 % + 0.583 * 35 %) Nm

3, special number Ntex and metric Nm

Ntex × Nm = 1000

4, special number Ntex and number Nden

Nden = 9 * Ntex

Twist degree and twist coefficient of yarn

1. Twisting: the number of twists per unit length of yarn. The Ttex(number) twist of cotton yarn and cotton-type chemical fiber yarn is represented by the number of twirls in the length of the yarn 10cm; The imperial branch number system, Te, is represented by an inch number of turns. The twist Tm of worsted yarn and chemical fiber filament is expressed in terms of the number of twists per meter. The relationship between the above methods is:

Ttex = 3.937 Te = Nm/10 Te = 0.254 Ttex = 0.0254 Tm

The twist is divided into Z and S. After the fibers in the yarns in the yarns are twisted, the direction from the bottom up and from right to left is called S <UNK>; From the bottom up, from left to right is called Z <UNK>.

The expression of the twist of the stock yarn thread, the first letter represents the twist direction of the single yarn, and the second letter represents the twist direction of the stock yarn thread. After two twisted stock yarn threads, the first letter represents the twist of the single yarn, the second letter represents the initial twist, and the third letter represents the double twist. For example, the single yarn is Z twist and the first twist is S twist. For the Z twist stock yarn thread, the twist is represented by ZSZ.

2. Twisting coefficient

Special number twist coefficient αtex = Ttex * Ntext 1/2

British twist coefficient αe = Te/Ne1/2

Metric coefficient αm = Tm/Nm 1/2

The relationship between the special number twist coefficient αtex and the imperial twist coefficient αe is:

αtex = Ttex * Ntext 1/2 = Te/2 .54 * 10 * 5831/2 * Ne1/2(583 is the coefficient of pure cotton varieties, if it is blended, fiber yarn, please refer to the special number and the English conversion constant C change)

Strength of yarn and breaking strength of single yarn

Single yarn strength: the force required to break a single yarn, called single yarn strength or single yarn strength, in cattle(N), Cniu(CN).

Single yarn fracture strength: The ratio of single yarn strength P to yarn special number Ntex is Km or cN/tex

Standard Yarn Weight

The weight of a textile material at a set moisture rate or a set moisture content is called "standard weight"

The relationship between the standard weight of textile materials and the nominal weight at the actual moisture return rate is:

Textile yarn standard weight = weight *(100 + metric return rate) /(100 + actual return rate)

Calculation of standard weight in production. The material is often dried first and calculated according to the drying weight. The formula is as follows:

Standard weight = dry weight of material(100 + metric return rate) / 100

yarn is a continuous linear material made of various textile fibers. It is fine and soft and has the basic properties required for textile processing and final product use. Yarns are mainly used for weaving shuttle fabrics, knitted fabrics, knitted fabrics, and some non-woven fabrics. A small number of them are directly in the form of linear textiles, such as various sewing lines, plush yarn threads, embroidery yarn threads, ropes, and other miscellaneous yarn threads.

Textile yarns by raw material type:

First, pure yarn

Pure yarn consists of the same kind of fiber, such as pure cotton yarn, wool yarn, sticky fiber yarn, acrylic yarn, polyester yarn, nylon yarn and so on.

Blended(mixed) yarn

Mixture or intertwined yarn is a yarn consisting of two or more fibers, such as polyester / cotton, wool / polyester, wool / nitrile, polyester / visco/nitrile, silk yarn / cotton, etc.. Short fiber yarn with more than two kinds of short fibers, called mixed yarn; A yarn made of more than two kinds of long textile silk yarns(such as twisted yarns) is called a blended yarns. Its blending ratio is as follows:

Xa = Wa/W * 100 % of which Xa is the content of some component fiber

Wa is the weight of the component fiber

W is the weight of the blended yarn

Textile yarn series

Series 1. Short fiber textile yarn

Short fiber yarns are yarns made from various kinds of short fiber by spinning technology. Usually, the short fiber is first spun into a single yarn by the short fiber yarn system, and then a few single yarns are merged and twisted to form a stock yarn thread. If several stock yarn threads are further combined and combined, it becomes a compound stock yarn thread. The stock yarn thread is used much more in woolen fabrics. Which form of single yarn, stock yarn thread and double twist stock yarn thread is used in the fabric shall be determined according to the design requirements and usage characteristics of the fabric.

Series 2. Continuous silk yarn(filament or silk)

1, Textile silk yarn

Using cocoon silk yarn on silkworm cocoon as raw material, the continuous filament obtained by multiple cocoon silk composite clusters is called cocoon silk yarn because it contains silk yarn gel, commonly known as raw silk yarn, and factory silk yarn. Several filaments are combined and twisted to form a silk thread, which contains glue and degumming. Silk filament yarn is an important raw material in silk yarn industry and is mainly used for processing various silk yarn fabrics.

2, Chemical fiber textile silk yarn

Chemical fiber yarns are clustered into yarns at the same time as the fibers are formed. They do not need to be assembled into yarns by the short fiber spinning process as chemical short fibers, and then woven into various types of fabrics. Compared with each other, the former has a high production efficiency. And although it is made of the same kind of fiber, the long silk yarn and the short fiber yarn are very different in style.

Fiber forming polymers form continuous filaments through a wire jet board. The number of fibers contained in the wire strips depends on the number of filaments on the thread jet board. The single-hole yarn thread jet board emits a single hole long silk yarn(commonly known as glass thread)., that is, single Kongsi, It can be used for weaving transparent fabrics. A long silk yarn made of a porous wire jet head, called a double silk yarn, referred to as a double yarn thread. After the filamentous yarn is twisted, there is a long silk yarn, and a few long silk yarns are merged and twisted to form a stock yarn thread. Because the strand is composed of filaments, it is also called a silk yarn .

Series 3. stock line

The yarn formed by the accumulation of two or more single yarns, which are combined with two or more yarns, is called a stock thread, referred to as a thread. If necessary, multiple strands can also be gathered again by merging and twisting into another yarn. Such yarn is called a double-twisted strand. The single yarn used to form the stock thread can be either a short fiber yarn or a long silk yarn; It can be the same fiber raw material, can also be different fiber raw materials, can be the same as short fiber yarn, can also be different.

Series 4. File/fiber composite yarn made of a combination of short fiber and long silk yarn

Cluster by short fiber and silk yarn.